Jinguan Electric, founded in 1979 as a high-tech enterprise in Nanyang City, Henan Province, China, has evolved from its pioneering role in arrester manufacturing to a global leader in high-voltage transmission and distribution equipment. Embracing Industry 4.0 principles, Jinguan Electric drives core competitiveness through continuous innovation, with TiraThai serving as its focused brand for specialized transformer solutions. This sub-brand channels Jinguan Electric's expertise into robust, customizable electroslag furnace transformers that integrate seamlessly with advanced remelting systems, delivering reliable power for precision metallurgy. Our transformers are designed to meet stringent international standards, including UL, CUL, CCC, CQC, CTQC, CE, and SGS certifications, while upholding ISO9001, ISO14001, and ISO45001 management systems.

The TiraThai Electroslag Furnace Transformers feature on-load tap changing (OLTC) for large units and no-load tap changing for smaller models, with impedance adjustments via series reactor switching or HV winding reconfiguration. Customizable for voltage, frequency, and regional specialties, they support capacities matched to furnace sizes—from compact setups for precision alloys to heavy-duty units for massive ingots. TiraThai's philosophy—"dig 100 meters deep in 1 meter of space"—reflects Jinguan Electric's commitment to meticulous engineering, ensuring these transformers withstand extreme thermal and electrical stresses while optimizing energy efficiency.

Transformer Model: Custom Electroslag Series Primary Voltage Ratings: Customizable (up to 35kV, based on furnace requirements) Secondary Voltage Ratings: Customizable (high-current output for remelting) Rated Capacity: Matched to furnace size (50-5000kVA or custom) Rated Frequency: 50/60Hz

This versatility makes TiraThai's electroslag furnace transformers essential for advanced metallurgical processes, providing stable, high-current power for superior material production worldwide.

Key Features and Engineering Excellence

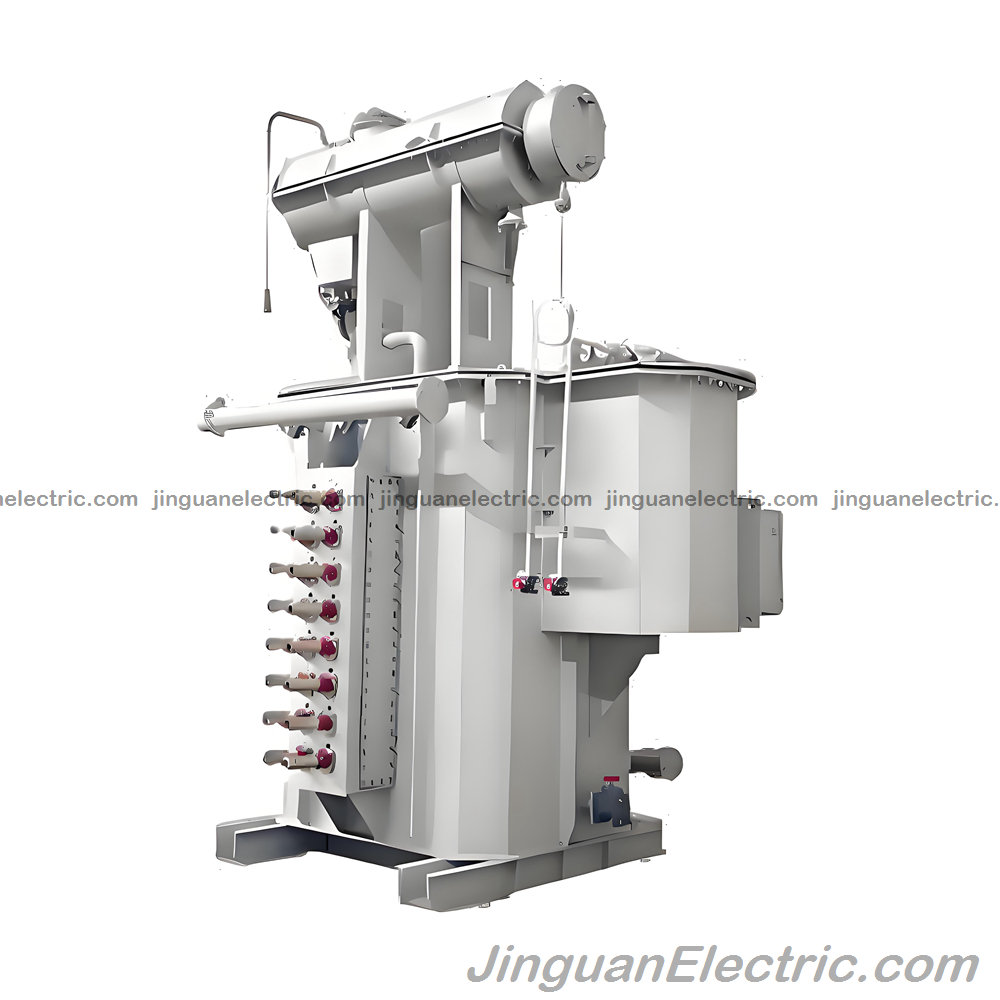

TiraThai's electroslag furnace transformers are engineered with cutting-edge features that enhance process control, safety, and efficiency in remelting operations. A standout capability is the realization of computer-controlled electroslag furnace remelting, integrating seamlessly with automation systems for precise parameter adjustments. The high-precision weighing system, combined with on-load voltage regulating transformers, ensures accurate material monitoring and power delivery, minimizing variations in the remelting process. The coaxial high-current power supply system delivers robust, stable output to the electrode, supporting high-throughput production without voltage drops.

The high-precision X-Y electrode adjustment system allows for fine-tuned positioning, optimizing slag pool dynamics and reducing defects in castings. An airtight inert gas shield protects the melt from oxidation, while the electrode tip preheating device accelerates startup and improves initial melt quality. Structurally, the core utilizes high-grade grain-oriented silicon steel with automated 45° full miter joints and punch-free processing, bound by fiberglass-free adhesive tape for minimal losses and enhanced mechanical stability. Coil technology employs an advanced main-longitudinal insulation structure with optimized winding designs, providing superior short-circuit and overload capacity—up to 150% for short durations—essential for the dynamic loads of electroslag furnaces.

These transformers exhibit high efficiency with minimal no-load and load losses, ensuring energy savings of 10-20% compared to legacy models. Safe and reliable operation is guaranteed through robust enclosures, pressure relief systems, and integrated fault detection, aligning with Jinguan Electric's rigorous quality protocols. Customizable impedance options—via series reactors or HV reconfiguration—adapt to specific furnace demands, while the overall design promotes low noise (under 60dB) and compact footprints for industrial integration. Jinguan Electric's automated production lines, including precision core cutting and vacuum drying, deliver defect-free units ready for global deployment.

These features not only meet but exceed international benchmarks, empowering metallurgists with tools for consistent, high-yield production of premium alloys and castings.

Technical Specifications

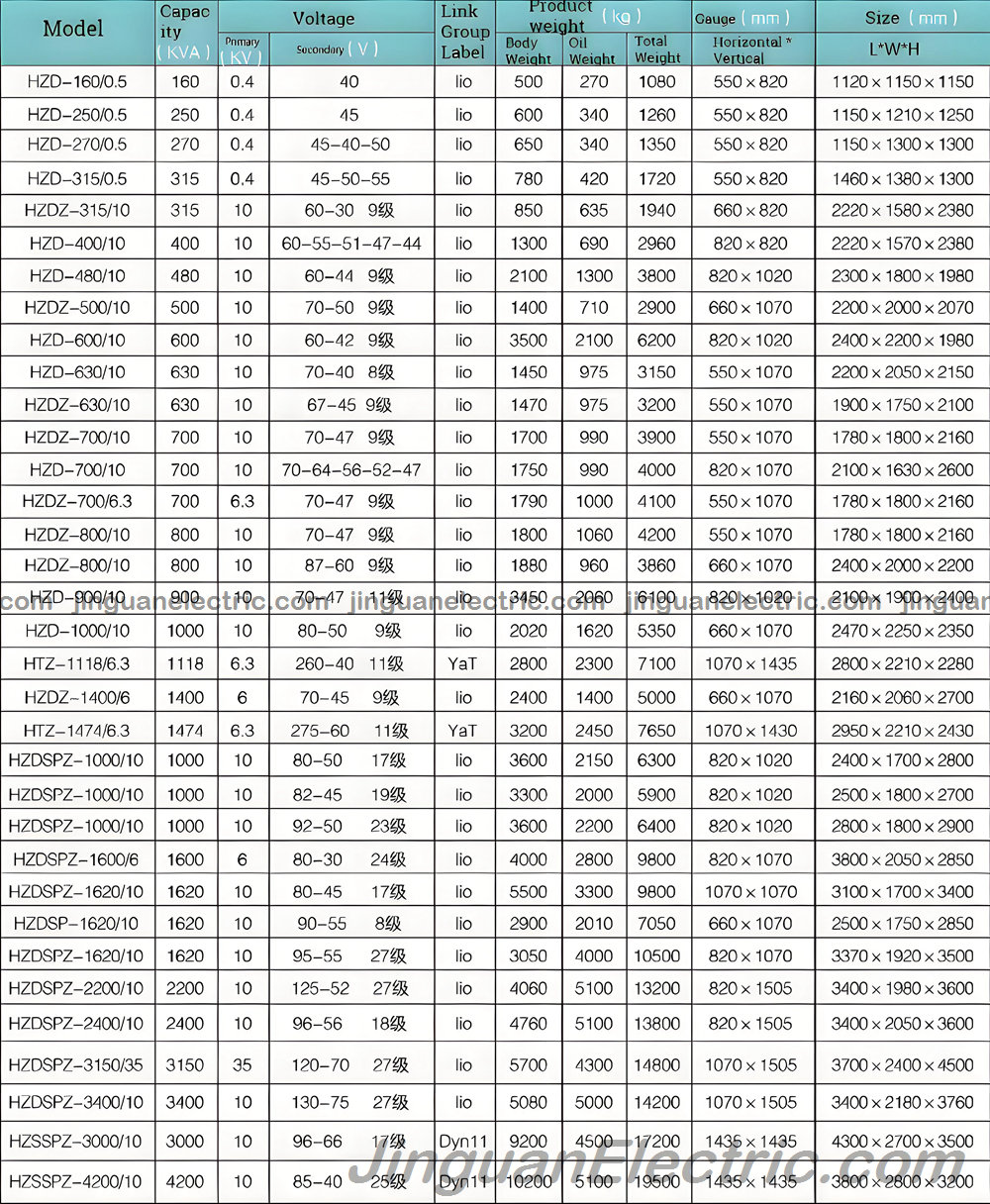

TiraThai's electroslag furnace transformers are precision-built for metallurgical excellence, with specifications tailored to furnace size and process needs. Below is a detailed overview of key parameters, derived from Jinguan Electric's validated testing and compliant with UL, CE, SGS, and ISO standards. Exact values are customizable based on application.

| Parameter | Specification Details |

|---|---|

| Rated Capacity (kVA) | 50-5000 (matched to furnace size, e.g., 100kVA for precision alloys; 2000kVA+ for large ingots) |

| Primary Voltage (kV) | Up to 35kV (customizable, e.g., 10kV/20kV for medium furnaces) |

| Secondary Voltage (V) | High-current output (customizable, e.g., 100-500V for electrode supply) |

| Voltage Regulation | On-load tap changing (OLTC) for large units; no-load for smaller (±5% or ±8×1.25% steps) |

| Impedance Adjustment | Series reactor switching or HV winding reconfiguration (4-10% range) |

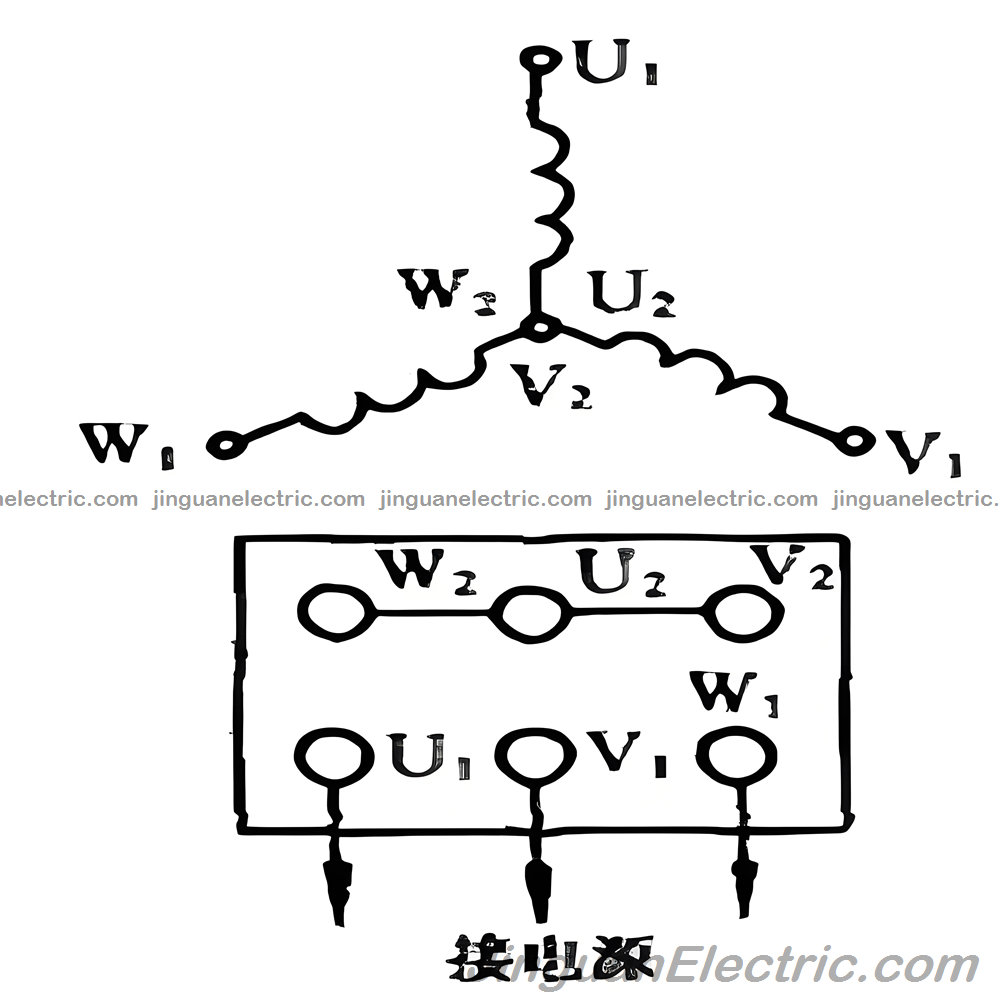

| Connection Type | Dyn11 or YNd11 (customizable for phase balance) |

| Core Material | High-grade grain-oriented silicon steel (45° miter joints, punch-free) |

| Winding Material | Oxygen-free copper (main-longitudinal insulation) |

| Insulation Class | Class A (105°C rise); H-class optional |

| Cooling Method | ONAN (Oil Natural Air Natural); ONAF optional |

| No-Load Loss (W) | Optimized (e.g., 1000kVA: 2000; 20% below standards) |

| Load Loss (W, at 75°C) | Optimized (e.g., 1000kVA: 12000; copper-optimized) |

| Short-Circuit Withstand | 40kA / 2s (superior overload capacity) |

| Noise Level (dB, 1m) | ≤60 at full load |

| Enclosure Protection | IP54 (industrial-grade, corrosion-resistant) |

| Efficiency (%) | >98 at full load |

| Frequency (Hz) | 50/60 |

These specs support operation in ambient temperatures -20°C to +50°C, with full type testing for thermal cycling, dielectric strength, and short-circuit resilience. Custom enhancements include integrated computer interfaces for remelting control.

Applications and Performance Benefits

TiraThai's electroslag furnace transformers are pivotal in advanced metallurgy, enabling the remelting of consumable electrodes to produce ultra-pure materials. In aviation and aerospace, they facilitate the creation of bearing steels and superalloys with minimal impurities, ensuring components withstand extreme stresses. Resistance and precision alloys for electronics and instrumentation benefit from the transformer's stable high-current supply, yielding materials with tight tolerances and enhanced magnetic properties.

Non-ferrous metal production, such as titanium or nickel alloys, leverages the inert gas shielding and precise electrode control for contamination-free melts. For heavy industry, these transformers power the forging of large-scale alloy steel ingots (hundreds of tons), slabs, and custom castings like turbine blades or pressure vessels, reducing defects and improving yield rates by 15-25%. In research and development, smaller units support pilot-scale remelting for alloy experimentation, accelerating innovation in materials science.

Real-world performance from Jinguan Electric deployments shows MTBF exceeding 50,000 hours, with energy efficiency cutting operational costs by 20% in continuous processes. The coaxial power system and X-Y adjustments minimize electrode wear, extending consumable life and supporting sustainable manufacturing in global foundries.

Why Choose TiraThai by Jinguan Electric?

TiraThai, as Jinguan Electric's sub-brand for specialized transformers, delivers electroslag excellence backed by over 45 years of metallurgical innovation. Our units offer unmatched customization for furnace integration, superior short-circuit handling, and computer-controlled precision that outperforms standard models. With global certifications like UL, CE, and SGS, plus eco-friendly designs, we ensure 25% higher yields and lower TCO, fostering partnerships in alloy production worldwide.

Expanded FAQ Section

How are TiraThai transformers shipped internationally? Shipments via sea, rail, or truck for overseas delivery. Main body in bulk packaging for stability, accessories in wooden cases to withstand transit stresses.

Can TiraThai products be customized? Yes, tailored for voltage, capacity, tap changers, and regional standards through Jinguan Electric's engineering team for optimal furnace matching.

What warranty do you provide? At least two years comprehensive coverage for defects, performance, and materials, with extensions for industrial applications.

Is Factory Acceptance Testing (FAT) supported? Standard: Full electrical, thermal, and mechanical tests per unit, with client witnessing available in-person or remotely.

Do you provide after-sales engineering support? Yes, Jinguan Electric assigns dedicated engineers for on-site installation, process integration, troubleshooting, and ongoing optimization.

What makes them suitable for electroslag remelting? High-current coaxial supply, precise X-Y adjustment, and OLTC ensure stable melting with minimal impurities for premium alloys.

Are inert gas shielding features included? Yes, airtight systems protect melts from oxidation, integrated with electrode preheating for efficient startups.

Certifications and Quality Assurance

All TiraThai products, supplied through Jinguan Electric, undergo national type testing including UL, CUL, CCC, CQC, CTQC, CE, and SGS certifications, plus mandatory product approvals. We maintain ISO9001 (quality), ISO14001 (environmental), and ISO45001 (occupational health) systems, audited annually for sustained excellence in metallurgical applications.

Contact Us Today

Elevate your electroslag processes with TiraThai's Electroslag Furnace Transformers. For inquiries, quotes, or custom designs:

- WhatsApp: +8613037600603

- Email: [email protected] or [email protected]

Our team responds within 24 hours to power your metallurgy.

Add New Comment