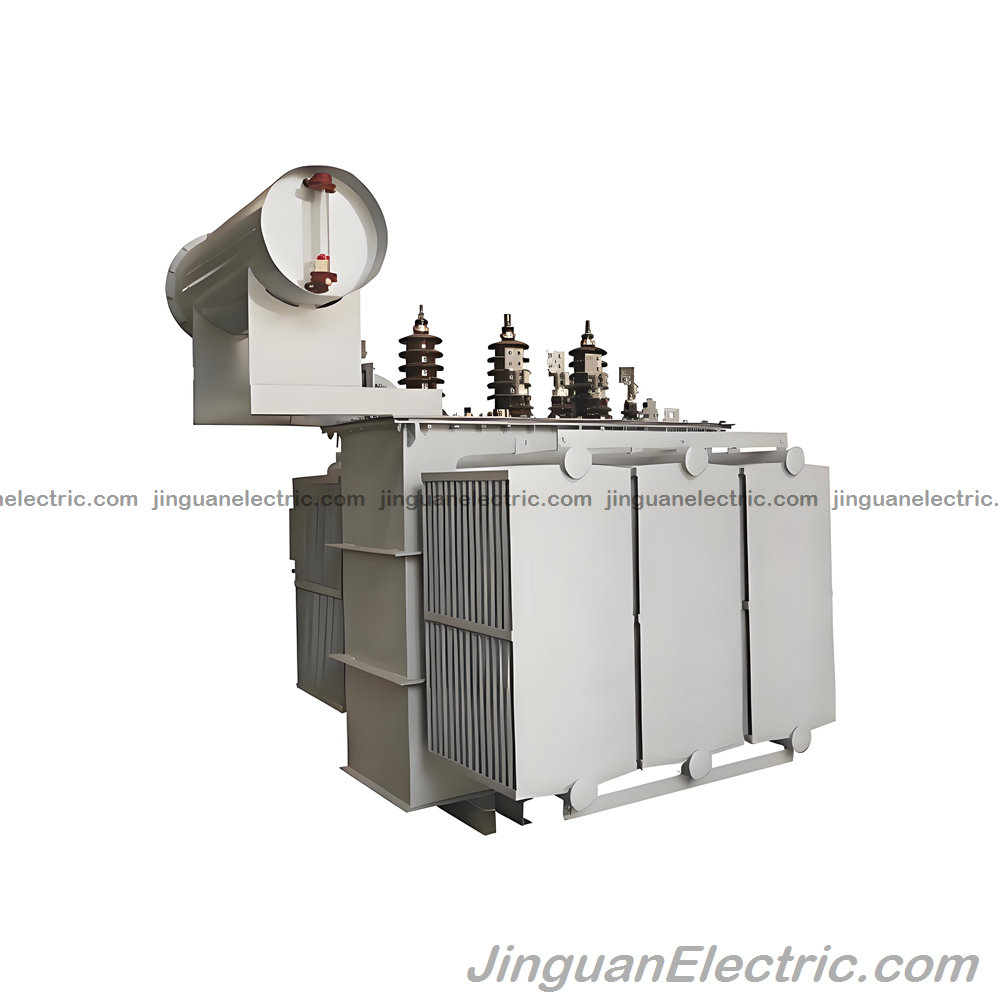

TiraThai, a specialized sub-brand of Jinguan Electric dedicated to transformer and electrical equipment innovations, proudly introduces the Intermediate Frequency Furnace Transformers. These high-efficiency, energy-saving units are engineered for intermediate frequency (IF) furnace systems, delivering reliable power transformation for industrial smelting, melting, and heat treatment processes. Developed through years of research, TiraThai's transformers significantly reduce operational costs, enhance system performance, and have earned acclaim from customers worldwide for their reliability and adaptability.

Jinguan Electric, founded in 1979 as a high-tech enterprise in Nanyang City, Henan Province, China, has evolved from pioneering arrester manufacturing to a global leader in high-voltage transmission and distribution equipment. Embracing Industry 4.0 principles, Jinguan Electric drives core competitiveness through continuous innovation, with TiraThai serving as its focused brand for specialized transformer solutions. This sub-brand channels Jinguan Electric's expertise into customizable IF furnace transformers that prioritize energy efficiency, low noise, and minimal interference, meeting international standards like IEC 60076-1:1993, GB 1094.1-1996, GB 6451-2008, and JB/T 10088-2004. Certified by UL, CUL, CCC, CQC, CTQC, CE, and SGS, these transformers ensure compliance with ISO9001, ISO14001, and ISO45001 management systems.

TiraThai's Intermediate Frequency Furnace Transformers feature customizable configurations to accommodate global variations in voltage, frequency, and regional specialties. With primary voltages of 10kV/35kV (or custom), secondary voltages from 220V-850V, capacities ranging from 10-1000kVA, and support for 50/60Hz frequencies, they integrate seamlessly into diverse IF furnace setups. Material options include copper or aluminum windings, with connection types like Yyn0 or Dyn0. The design philosophy—"dig 100 meters deep in 1 meter of space"—reflects Jinguan Electric's commitment to precision, ensuring these transformers withstand industrial stresses while delivering substantial economic benefits, such as 17.2% lower costs over 10 years compared to traditional integrated substations.

Transformer Model: Custom IF Furnace Series Primary Voltage Ratings: 10kV/35kV (Customizable) Secondary Voltage Ratings: 220V-850V (Customizable) Rated Capacity: 10-1000kVA (Customizable) Rated Frequency: 50/60Hz

This versatility makes TiraThai's IF furnace transformers ideal for high-frequency industrial applications, optimizing power delivery for efficient, cost-effective operations.

Key Features and Engineering Excellence

TiraThai's Intermediate Frequency Furnace Transformers are distinguished by their advanced engineering, focusing on energy conservation, reduced interference, and operational reliability. Key innovations include a 40%-50% reduction in no-load losses and 7%-10% decrease in load losses through optimized core and winding designs, utilizing high-permeability silicon steel and low-resistivity conductors. The no-load current is slashed by 90%, minimizing line losses and improving overall system efficiency, while magnetic flux leakage is reduced by 50% to eliminate electromagnetic interference with nearby equipment.

Ultra-quiet operation achieves a 10-15 dB noise reduction via vibration-dampened cores and sound-absorbent enclosures, ensuring compliance with JB/T 10088-2004 sound level standards. Material efficiency saves 20%-30% on copper and iron costs through streamlined construction, without compromising durability. The transformer's robust insulation system, with resistance >5MΩ, supports high-frequency performance up to 60Hz, preventing hotspots and extending service life beyond 30 years.

Jinguan Electric's automated production processes—featuring precision winding, vacuum impregnation, and AI-driven quality inspections—guarantee defect-free units. Optional features like on-load tap changers (OLTC) for voltage regulation and integrated monitoring for real-time diagnostics enhance process control in dynamic IF furnace environments. Compared to conventional transformers, TiraThai models deliver remarkable economic benefits, including lower energy bills and reduced maintenance, making them a superior choice for sustainable industrial power.

These features not only meet but exceed IEC 60076-1:1993 and GB 1094.1-1996 standards, providing users with a transformer that optimizes IF furnace productivity while minimizing environmental and operational impacts.

Technical Specifications

TiraThai's Intermediate Frequency Furnace Transformers are precision-engineered for industrial reliability, with customizable parameters to fit specific furnace requirements. Below is a comprehensive table of key specifications, derived from Jinguan Electric's validated testing and aligned with IEC 60076-1:1993, GB 1094.1-1996, GB 6451-2008, and JB/T 10088-2004 standards.

| Parameter | Specification Details |

|---|---|

| Rated Capacity (kVA) | 10-1000 (customizable, e.g., 500kVA for medium furnaces) |

| Primary Voltage (kV) | 10 / 35 (customizable) |

| Secondary Voltage (V) | 220-850 (customizable) |

| Frequency (Hz) | 50/60 |

| Winding Material | Copper / Aluminum (customizable) |

| Winding Connection | Yyn0 / Dyn0 (customizable) |

| Insulation Resistance (MΩ) | >5 (at 1000V DC) |

| No-Load Loss Reduction | 40%-50% below standards |

| Load Loss Reduction | 7%-10% below standards |

| No-Load Current Reduction | 90% below standards |

| Noise Reduction (dB) | 10-15 below standards |

| Magnetic Flux Leakage Reduction | 50% below standards |

| Insulation Class | Class A (105°C rise) |

| Cooling Method | ONAN (Oil Natural Air Natural) |

| Efficiency (%) | >98 at full load |

| Short-Circuit Withstand | 25x rated current / 2s |

| Enclosure Protection | IP54 (industrial-grade) |

| Economic Benefit (10 Years) | 17.2% lower costs vs. traditional substations |

These metrics support operation in ambient temperatures from -25°C to +40°C and altitudes up to 1000m, with full routine testing for dielectric strength, thermal rise, and sound levels. Custom enhancements include OLTC for dynamic regulation and eco-oils for sustainability.

Applications and Performance Benefits

TiraThai's Intermediate Frequency Furnace Transformers are tailored for high-frequency industrial heating and melting processes, powering IF furnaces in metallurgy, forging, and manufacturing. In steel and non-ferrous metal production, they enable efficient remelting of alloys, scrap, and ingots, supporting capacities from small-scale precision work to large-batch smelting with minimal energy waste. Heat treatment applications, such as quenching and annealing in automotive and aerospace parts fabrication, benefit from the transformer's stable output, ensuring uniform heating and reduced cycle times.

Foundries and casting operations deploy these units for induction melting of iron, aluminum, and copper, where low interference prevents disruptions to adjacent CNC machines or sensors. In global manufacturing hubs, TiraThai transformers facilitate energy-efficient upgrades, cutting utility costs by 20-30% through loss reductions. Performance data from Jinguan Electric installations reveals MTBF over 50,000 hours, with 90% no-load current savings translating to significant standby efficiency in intermittent operations.

The quiet, low-leakage design suits urban industrial parks, minimizing noise pollution and electromagnetic compatibility issues. Overall, these transformers boost productivity by 15-25%, aligning with sustainable manufacturing goals through material and energy savings.

Why Choose TiraThai by Jinguan Electric?

TiraThai, as Jinguan Electric's sub-brand for specialized transformers, offers unmatched IF furnace solutions backed by 45+ years of innovation. Our models deliver 40-50% no-load loss cuts, ultra-quiet operation, and full customization for global variances, outperforming standards. With certifications like UL, CE, and SGS, plus eco-friendly designs, we ensure 17.2% long-term cost savings and reliable performance, empowering industrial partners worldwide.

Expanded FAQ Section

How are TiraThai transformers shipped internationally? Shipped via sea, rail, or truck for overseas delivery. Main body in bulk packaging for stability, accessories in wooden cases to withstand transit stresses.

Can TiraThai products be customized? Yes, tailored for voltage, frequency, capacity, and regional specialties through Jinguan Electric's engineering team.

What warranty do you provide? At least two years comprehensive coverage for defects, performance, and materials, with extensions available.

Is Factory Acceptance Testing (FAT) supported? Standard: Full electrical, thermal, and mechanical tests per unit, with client witnessing in-person or remotely.

Do you provide after-sales engineering support? Yes, Jinguan Electric assigns dedicated engineers for installation guidance, troubleshooting, and ongoing inquiries.

What makes them energy-efficient? 40-50% no-load loss reduction, 90% lower no-load current, and 7-10% load loss cuts optimize IF furnace operations.

Are they suitable for high-frequency use? Yes, designed for 50/60Hz with low interference and flux leakage, ensuring stable performance in smelting.

Certifications and Quality Assurance

TiraThai products, supplied through Jinguan Electric, undergo national type testing: UL, CUL, CCC, CQC, CTQC, CE, SGS, and mandatory approvals. Certified to ISO9001 (quality), ISO14001 (environment), and ISO45001 (health & safety), ensuring compliance with IEC 60076-1:1993, GB 1094.1-1996, GB 6451-2008, and JB/T 10088-2004 for global excellence.

Contact Us Today

Optimize your IF furnace with TiraThai's Intermediate Frequency Furnace Transformers. For quotes or custom designs:

- WhatsApp: +8613037600603

- Email: [email protected] or [email protected]

Our team responds within 24 hours.

Add New Comment