TiraThai, a specialized sub-brand of Jinguan Electric dedicated to transformer and related electrical equipment, introduces the 110kV class three-phase oil-immersed power transformers. These high-voltage powerhouses are essential for long-distance transmission and large-scale distribution, providing stable, efficient energy transfer in utility-scale applications. Manufactured in strict accordance with International Electrotechnical Commission (IEC) standards and People's Republic of China GB1094.1-2-1996/GB1094.3-1985 norms, TiraThai's 110kV transformers deliver exceptional impact resistance, superior mechanical strength, robust short-circuit withstand capabilities, reduced noise levels, minimized losses, excellent sealing, and low-maintenance requirements.

Jinguan Electric, founded in 1979 as a high-tech enterprise in Nanyang City, Henan Province, China, has evolved from pioneering arrester production to a global leader in high-voltage transmission and distribution systems. Embracing Industry 4.0 technologies, Jinguan Electric drives innovation and core competitiveness, with TiraThai serving as its flagship brand for transformer solutions. This sub-brand focuses on advanced power equipment, ensuring that our 110kV transformers integrate seamlessly into modern grids, supporting everything from national interconnectors to industrial mega-complexes. Our design ethos—"dig 100 meters deep in 1 meter of space"—embodies Jinguan Electric's craftsman-like precision, guaranteeing reliability in the most demanding environments.

Key Model Highlights:

- Primary Voltage Ratings: 110kV (customizable to 66-132kV)

- Secondary Voltage Ratings: 10-35kV (customizable)

- Rated Capacity: 31.5-300MVA (or custom)

- Rated Frequency: 50/60Hz

- Connection Type: YNd11 (or custom)

These specifications enable flexible deployment, from step-down substations to generator step-up roles, all while prioritizing safety and efficiency for global infrastructure projects.

Advanced Features and Engineering Benefits

TiraThai's 110kV oil-immersed transformers are engineered for peak performance, incorporating premium materials and innovative designs that set new benchmarks in the high-voltage sector. The core utilizes high-grade, low-loss silicon steel laminations, stacked with stepped-lap joints to minimize magnetic flux leakage and hysteresis losses, achieving up to 25% better efficiency than legacy models. Windings are crafted from high-conductivity, oxygen-free copper, wound in continuous disc or helical configurations to enhance mechanical integrity and thermal distribution, ensuring the unit can endure short-circuit currents exceeding 40kA for 2 seconds without deformation.

The tank assembly features heavy-gauge welded steel with anti-corrosion coatings, equipped with expandable radiators for superior ONAN/ONAF cooling—natural oil natural air for base loads, with optional forced air for peak demands. This hybrid cooling extends overload capacity to 150% for extended periods, ideal for fluctuating grid conditions. Sealing is achieved through nitrile rubber gaskets and welded flanges, creating a hermetically sealed environment that prevents oil contamination and oxidation, thereby extending service life beyond 40 years with minimal interventions.

Noise reduction is a priority, with core clamping systems and vibration-dampening mounts limiting operational sound to under 65dB at full load, facilitating installations in urban or noise-regulated zones. Integrated accessories include on-load tap changers (OLTC) with ±8x1.25% steps for voltage regulation, Buchholz relays for gas detection, and pressure relief vents to mitigate internal faults. The oil preservation system employs a conservator with silica gel breathers, maintaining dielectric strength in varying climates. Jinguan Electric's state-of-the-art production facilities, featuring automated winding machines and vacuum oil-filling stations, ensure each transformer meets exacting tolerances, reducing field commissioning time by up to 30%.

These features not only comply with rigorous standards but also deliver tangible benefits: lower total ownership costs through reduced energy losses (typically 0.5-1% of throughput), enhanced grid stability, and simplified asset management via optional IoT-enabled monitoring for real-time diagnostics.

Comprehensive Technical Specifications

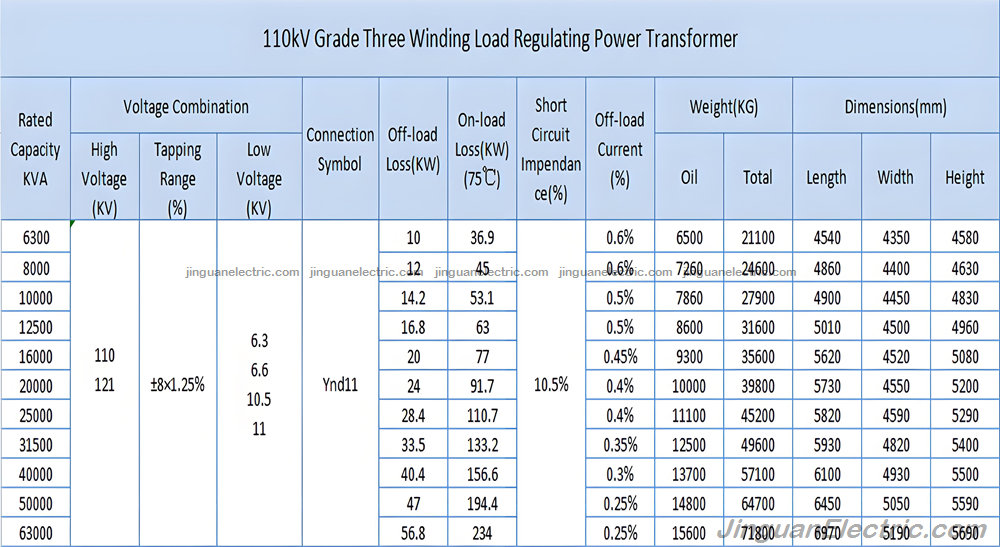

TiraThai 110kV transformers are precision-engineered for versatility, with baseline specs customizable to client needs. The following table outlines key parameters, validated through Jinguan Electric's certified testing protocols.

| Parameter | Specification Details |

|---|---|

| Rated Capacity (MVA) | 31.5, 40, 50, 63, 80, 100, 125, 160, 200, 250, 300 (custom up to 400) |

| Primary Voltage (kV) | 110 (Y connection; customizable to 66/110/132) |

| Secondary Voltage (kV) | 10 / 20 / 35 (Dyn11 or YNd1) |

| HV Tap Changer | ±8×1.25% or ±5×0.5% (on-load, OLTC standard) |

| Frequency (Hz) | 50/60 |

| No-Load Loss (kW) | 31.5MVA: 20; 100MVA: 45 (low-loss core design) |

| Load Loss (kW, at 75°C) | 31.5MVA: 150; 100MVA: 400 (copper-optimized) |

| Impedance Voltage (%) | 10-14% (capacity-dependent, adjustable) |

| Insulation Level | LI200/AC95kV (lightning impulse, AC withstand) |

| Cooling Method | ONAN/ONAF; OFAF optional for ultra-high loads |

| Noise Level (dB, 1m) | ≤65 at full load |

| Enclosure Protection | IP54 standard; IP65 for harsh environments |

| Oil Volume (m³, approx. 100MVA) | 25-35 (high-grade mineral or synthetic) |

| Weight (tons, approx. 100MVA) | Total: 120-150 (core & windings: 60) |

| Short-Circuit Withstand | 40kA / 2s (dynamic and thermal) |

These metrics align with executive standards including GB1094.1/2-1996 (power transformers), GB1094.3/5-2003 (insulation and short-circuit), GB/T6451-2008 (three-phase oil-immersed parameters), GB311.1-1997 (insulation coordination), and JB/T10318-2002 (amorphous core options). Optional amorphous cores further slash no-load losses by 70%, supporting eco-friendly upgrades.

Applications and Operational Excellence

TiraThai's 110kV oil-immersed transformers are deployed in mission-critical scenarios, leveraging their robustness for uninterrupted power flow. In high-voltage transmission networks, they act as interconnectors between generating stations and regional grids, stepping down voltage for efficient long-haul delivery while minimizing line losses. Utility substations worldwide rely on them for load balancing, with OLTC enabling adaptive voltage control amid renewable influxes.

Industrial giants—such as aluminum smelters, semiconductor fabs, and offshore oil platforms—utilize these transformers for on-site power conversion, where their short-circuit resilience protects multimillion-dollar assets from transients. Renewable energy corridors, including HVDC links for wind and solar farms, benefit from customizable impedances that dampen harmonics and stabilize frequencies. Infrastructure megaprojects, like smart cities and high-speed rail feeders, integrate them for scalable expansion, with low-noise variants suiting populated areas.

Performance data from Jinguan Electric installations indicates MTTR under 4 hours for routine maintenance, with energy efficiency yielding 10-15% annual savings in large grids. Their adaptability spans climates, from Siberian winters to Middle Eastern deserts, proven in exports to over 50 countries.

Why Choose TiraThai by Jinguan Electric?

As Jinguan Electric's sub-brand specializing in transformers, TiraThai offers unmatched expertise, inheriting 45+ years of innovation in high-voltage solutions. Our 110kV models provide superior value through low-loss designs, global compliance, and sustainable features like biodegradable oils. Backed by Jinguan Electric's ecosystem, we ensure rapid prototyping, on-time delivery, and comprehensive support, outperforming competitors in lifecycle economics by 20-25%.

Detailed FAQ Section

How are TiraThai transformers shipped? Transformers are shipped via sea, train, or truck for international destinations, with the main body in secure bulk packaging and accessories in reinforced wooden cases to withstand transit stresses and arrive fully intact.

Can TiraThai products be customized? Yes, considering global differences in voltage, frequency, and environmental factors, our 110kV transformers can be fully tailored to your specifications, leveraging Jinguan Electric's engineering prowess for optimal fit.

Do you offer a guarantee for the products? Absolutely. We provide at least a two-year comprehensive warranty on all transformers, covering manufacturing defects, performance guarantees, and material durability.

Do you accept Factory Acceptance Testing (FAT)? Yes, FAT is standard for every unit. We conduct thorough electrical, mechanical, and thermal tests, with client witnessing available in-person or remotely to ensure total satisfaction.

Do you assign engineers for after-sale service? Certainly. Jinguan Electric deploys dedicated engineers for on-site installation guidance, operational training, troubleshooting, and ongoing inquiries to support seamless long-term performance.

What makes your sealing and maintenance features superior? Our hermetic sealing with anti-aging gaskets and conservator systems minimizes leaks and contamination, reducing maintenance to annual oil checks and extending intervals by 50% over traditional designs.

Are high-seismic options available? Yes, with bolted core clamps and base isolators rated for 0.5g+ accelerations, ideal for seismic zones while maintaining full operational integrity.

Certifications and Quality Assurance

All TiraThai products, supplied through Jinguan Electric, undergo national type testing including UL, CUL, CCC, CQC, CTQC, CE, and SGS certifications, alongside mandatory product approvals. We uphold a comprehensive management system with ISO9001 (quality), ISO14001 (environmental), and ISO45001 (occupational health) certifications, audited regularly for sustained excellence. This ensures our 110kV transformers meet the highest global benchmarks for safety, reliability, and sustainability.

Contact Us Today

Secure your power transmission future with TiraThai's 110kV Class Oil-Immersed Transformers. For inquiries, quotes, or expert advice:

- WhatsApp: +8613037600603

- Email: [email protected] or [email protected]

Our team responds within 24 hours—let's collaborate on your next project.

Add New Comment